Pricing

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua.

ViciVision America Shaft Measuring Systems

ViciVision America offers manufacturers advanced measurement solutions for turned and flat components. These machines deliver the fastest measurements on the market using a combination of video and light projection, providing top-of-the-range performance in a practical, compact design.

ViciVision Machines for Turned Parts

ViciVision Machines are designed for the shop floor.

Techno

Given the wide scope of measurement ranges offered, this machine range is designed to adapt to current and future manufacturing demands. From 40 to 180 mm in diameter, and 300 to 1250 mm in length, the modular range of the Techno series can provide you with the most suitable machine for your production.

Keeping Production in Tolerance

Immediate inspection without the need to leave the wokstation significantly reduces machine downtime. Implementing the preventive actions indicated by the measurement trend graphs reduces rejects.

VICIVISION Tool-Loop

It is possible to set the interface between MTL and the workstation to automatically correct tool parameters. This function eliminates human error and speeds up tool parameter settings. Each part produced is ready to be delivered.

Improving Productivity

Operators are more independent during inspection. Tool offsets can be adjusted before parts become out of tolerance, reducing the amount of rejects produced.

Cutting-Edge Software

The MTL 8.10 version is designed to improve the control phase and further extend the number of possible measurements. It includes specific tools for static and dynamic measurements, and dedicated tools for threads nuts, camshafts, turbines, etc. Automatic features help the operator to get measurements: self-programming, automatic loading of the part program, step by step assisted programming, DXF comparison.

Measurements Report

The software allows the operator to print or export complete and custom pdf measurement reports. Results of measurements on histograms for immediate consultation.

-

Superior Accuracy

MTL X5

Measuring the Smallest Details

MTL X5 are optical measuring machines specifically designed to measure micro-mechanical parts, dental implants, watch parts and micro-parts in general.

These high resolution machines detect even the smallest details. Measuring tools designed for every need: static measurements, hexagon, and threads analysis.

An all-in-One Solution for Every Measurement

The MTL X5 enables operators to inspect production without specific measurement know-how. The part program is activated with a simple click and dozens of measurements are taken in a few seconds resulting in a positive or negative feedback on the component.

- A clear-cut solution for dental implantology and biomedical technology

- The high resolution, one of a kind in its category, detects even the smallest details

- Its direct access design facilitates loading and unloading of the most difficult to manage pieces

- No openings or undercuts means that small parts can be easily retrieved if they fall during operation

Cutting-Edge Software

The MTL 8.10 version is designed to improve the control phase and further extend the number of possible measurements. It includes specific tools for static and dynamic measurements, and dedicated tools for threads nuts, camshafts, turbines, etc. Automatic features help the operator to get measurements: self-programming, automatic loading of the part program, step by step assisted programming, DXF comparison.

-

Quality Engineering

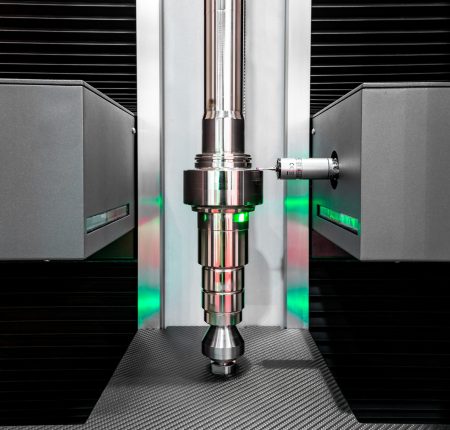

Touch Probe

One Measuring System, Many Choices

VICIVISION provides a completely new measuring function for shafts, combining the specific optical know-how method with a Touch Probe measuring system.

The Optical Measuring system, consisting of a telecentric lens, light source, rotation system and sensors, has long provided a wide list of measurements to hundreds of shafts producers.

Today, the combination of optical and tactile functions results in a complete measuring control for turned parts in just one cycle.

VICIVision’s unbeatable price-performance measuring system is now enriched with a Renishaw Scanning Probe mounted on the top of the light source. The probe is interchangeable and covers the whole length area.

While the optical measuring system quickly provides Static, Geometric and Thread measurements, as well as Form and Nut measurements, the touch system detects features that are not optically visible.

The optical and touch combo is available for addition to all new M Series, X Series, and Techno Range units.

This revolutionary probe system makes it possible for end users to measure:

-

Axial and Total Axial Run-out

-

Length

-

Planarity

-

Perpendicularity

-

Keyway width

-

Keyway depth

-

Keyway length